Cómo podemos ayudarte

En la preparación y pulido de superficies de hormigón, el diseño de herramientas de diamante con unión metálica Es crucial para lograr los resultados de rectificado deseados. Si bien el aglomerante y el tamaño del grano influyen en la eficacia de la herramienta, la forma física, o diseño del segmento, influye en la eficiencia del rectificado, los patrones de desgaste y la adaptabilidad a diversos tipos de superficie. Reconocer estas diferencias permite a los contratistas optimizar sus procesos para mejorar la eficiencia y la calidad del acabado.

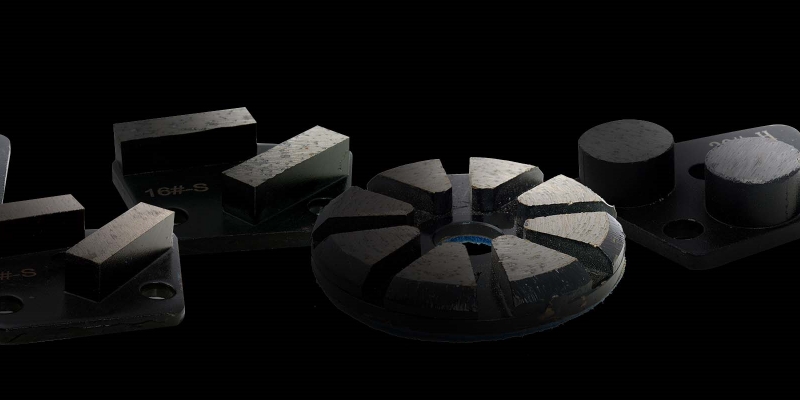

Los segmentos en forma de flecha se utilizan a menudo para el desbaste agresivo y la eliminación de recubrimientos. Su diseño puntiagudo concentra la presión en un área pequeña, lo que permite un corte rápido en superficies duras o la eliminación de materiales resistentes como epoxi o pintura. Esto facilita... Herramientas de rectificado de segmentos de flecha Especialmente eficaz durante las fases iniciales de molienda o cuando se requiere una eliminación significativa de material en un corto período de tiempo.

Los segmentos rectangulares o de barra proporcionan un efecto de pulido más uniforme y consistente. Estas formas distribuyen la presión uniformemente por toda la superficie, lo que las hace ideales para un pulido medio o alisado después de un desbaste agresivo. Ayudan a minimizar la profundidad de los arañazos y se utilizan frecuentemente para preparar pisos para niveles de grano más fino o etapas de pulido. Su patrón de desgaste uniforme también prolonga la vida útil de la herramienta.

Los segmentos redondos o de botón se utilizan generalmente para desbaste o bruñido ligero. Estas herramientas generan mínimos rayones y son excelentes para refinar superficies o trabajar con concreto más blando. Gracias a su menor área de contacto, discos de rectificado de segmentos redondos Pueden seguir de cerca las variaciones de la superficie, lo que produce mejores resultados en áreas detalladas o alrededor de los bordes. Sin embargo, son menos eficaces para la eliminación de material pesado.

Algunas herramientas combinan segmentos de diferentes formas en una sola placa, lo que permite obtener tanto fuerza de rectificado como refinamiento de la superficie en un solo paso. Por ejemplo, una combinación de segmentos de flecha y rectangulares permite que una herramienta realice un rectificado agresivo y, al mismo tiempo, logre un acabado superficial relativamente liso. La elección de la configuración depende de los objetivos específicos del trabajo, ya sea la eliminación de recubrimientos, la nivelación o la preparación para el pulido.

Elegir la forma correcta del segmento va más allá de la simple remoción de material; también implica consideraciones de eficiencia, consistencia y preparación de la superficie. Al adaptar la forma de la herramienta a la tarea específica y al estado del hormigón, los profesionales pueden mejorar el rendimiento y prolongar la vida útil tanto de las herramientas como del sistema de pisos.